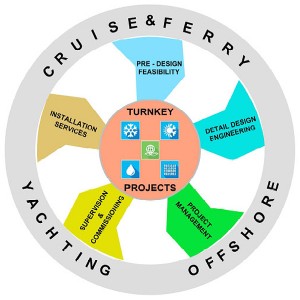

MTH was founded in July 2014. MTH is a team of highly skilled project managers, service technicians and design engineers, all of whom have been working in the shipbuilding industry for many years. Based on its team’s expertise and experience MTH’s intention is to be a reliable partner for turnkey services in the fields of HVAC, refrigeration and automation. The design and system integration work makes MTH a full turnkey contractor with very competent and responsible personnel. The present MTH personnel has been involved as the core team in a number of large scale modernisation projects for whole-ship HVAC contracts in the cruise ship as well as the yachting industry.

MTH is part of GTH (Gebaeude Technik Hamburg), a family-owned company providing technical and energy systems for buildings in the metropolitan area of Hamburg.

The new MTH Logo

MTH’s Guiding Principles

- We are a well-integrated team.

- We have high standards of quality.

- We strive for a long-term cooperation with our clients

- We are a reliable and predictable partner for customers and suppliers.